APPLICATIONS

Resources

Power Quality Management

What is power quality management?

Power quality management involves the systematic control and mitigation of various electrical disturbances and anomalies present in power systems to ensure the delivery of high-quality, reliable electricity to consumers. It encompasses measures to monitor, assess, and improve the characteristics of electrical power, thereby enhancing the efficiency, safety, and reliability of electrical systems.

What are four factors that contribute to power quality?

Four factors contributing to power quality include:

- voltage transients (or transients)

- voltage sags and surges

- harmonics

- interruptions or power failures.

These factors represent disturbances or variations in electrical power that can impact the performance and reliability of electrical equipment and systems.

What are types of power quality issues?

Power quality issues encompass a range of disturbances and anomalies in electrical power, including transients, voltage sags and surges, harmonics, interruptions or power failures, and bad power factor. These issues can manifest as disruptions or variations in voltage, frequency, and waveform, adversely affecting the performance and reliability of electrical systems.

Why is power quality management so important?

Power quality management is crucial due to the critical role of electrical power in modern society. Electrical power is essential for various applications, including industrial processes, commercial operations, and residential use. Poor power quality can lead to equipment failures, data loss, production downtime, and safety hazards, resulting in significant economic losses and operational inefficiencies. By ensuring high-quality, reliable power supply, power quality management contributes to the overall stability, efficiency, and safety of electrical systems.

How can Claude Lyons help?

Claude Lyons offers comprehensive solutions and expertise in power quality management to address a wide range of power quality issues.

Our services include site surveys, recommendations, and tailored solutions based on current and future needs.

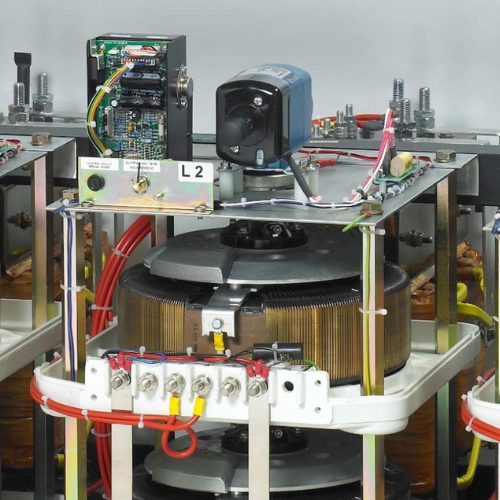

We provide a complete range of products and services, including UPS (Uninterruptible Power Supply) systems, isolation transformers, power line conditioners, and voltage stabilisers, designed to mitigate power quality issues and enhance system reliability. With our team of fully qualified engineering professionals, we deliver end-to-end support, from commissioning and installation to maintenance and service agreements. Contact us today to discuss how Claude Lyons can help resolve your power quality issues and ensure the reliability and efficiency of your electrical systems.

Voltage Stabilisers

Energy Saving

Transformers

CONTACT US

have a question regarding an application? Need more info? Contact us below!

ABOUT US

Claude Lyons, a UK brand established in 1918, has been a pioneer in voltage and power control, making significant advancements in energy saving and harmonic mitigation, and is globally recognised for its voltage stabilisers, power conditioning and uninterruptible power supplies (UPS). In 2016, Allendale Group Ltd acquired Claude Lyons’ trademarks, product designs, and intellectual property, continuing the legacy of innovation and commitment to high-quality products.

Allendale Group Ltd

Pindar Road

Hoddesdon

Hertfordshire

EN11 0BZ

United Kingdom

Tel: +44 (0)1992 455 930

Email: sales@claudelyons.com

Claude Lyons Ltd is a subsidiary company of Allendale Group Ltd.