Types of Power Problems

Types of Power Problems

Voltage Dip or Sags

What is a Voltage Sag?

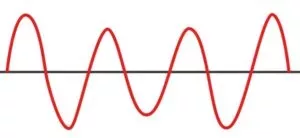

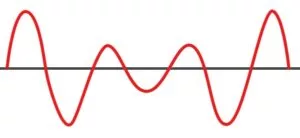

Voltage dips or sags, also known as voltage interruptions, are transient events characterised by short-duration reductions in the mains power supply voltage. As an electrical engineer, understanding the dynamics and implications of voltage dips is crucial for designing resilient electrical systems and ensuring equipment reliability.

Voltage dips typically last for several cycles, which means they occur over a brief period, usually less than a second but long enough to disrupt the normal operation of electrical equipment. These disturbances can arise from various sources such as sudden changes in load demand, grid faults, switching operations, or faults in the power distribution system.

When voltage dips occur, they can have significant consequences for sensitive electrical equipment. For instance:

Equipment Malfunction: Voltage dips can cause disruptions in the operation of sensitive equipment such as computers, industrial machinery, or control systems. The reduced voltage level may lead to erratic behavior, shutdowns, or even damage to the equipment.

Loss of Productivity: In industrial settings, voltage dips can halt production processes, leading to downtime and financial losses. For example, in manufacturing plants, interruptions in power supply can result in defective products, material waste, and delays in delivery schedules.

Data Loss: Voltage dips can affect electronic devices such as servers, data storage systems, or communication networks. Sudden voltage reductions may result in data corruption, loss of critical information, or system crashes, posing significant risks to business operations.

Safety Concerns: In certain applications, voltage dips can compromise safety systems or emergency equipment. For instance, in healthcare facilities, power disruptions due to voltage dips can impact the operation of life-support systems or medical equipment, endangering patient safety.

Define Voltage Sag

Voltage Sag is a term defined by the Institute of Electrical and Electronics Engineers (IEEE) in their Standard 1159. According to this standard, specifically in section 3.1.73, a voltage sag is delineated as a variation in the Root Mean Square (RMS) value of the voltage from its nominal level. This variation persists for a duration longer than half a cycle of the power frequency but does not exceed one minute.

In simpler terms, voltage sag refers to a temporary decrease in the voltage level of an electrical power system. This decrease lasts for a duration ranging from slightly longer than half of a cycle of the power frequency (which is typically 50 or 60 Hz) up to a maximum duration of one minute. Such occurrences are significant in power engineering as they can impact the performance and reliability of electrical equipment and systems.

What are the symptoms of a Voltage Sag?

Dimming of Lights: You might notice a temporary decrease in the brightness of lighting fixtures.

Equipment Issues: Sensitive devices may experience glitches or even shut down unexpectedly.

Possible System Restart: In severe cases, the entire system might need to be restarted to resume normal operation.

Are there specific industries susceptible to voltage sags?

Information Technology (IT) and data centers rely heavily on stable power to ensure continuous operation of servers, networking equipment, and storage systems. Voltage sags can disrupt data processing and communication, leading to downtime and potential data loss.

Manufacturing and industrial facilities often use sensitive machinery and automated processes that can be adversely affected by voltage sags. Production lines may halt or produce defective products, resulting in financial losses.

Healthcare facilities, such as hospitals, rely on uninterrupted power to operate life-support systems, medical devices, and electronic health records. Voltage sags can compromise patient care and safety by disrupting critical medical equipment.

Can voltage sags lead to long-term damage to electrical equipment?

While voltage sags typically last for a short duration, they can still cause long-term damage to electrical equipment under certain circumstances.

Repeated exposure to voltage sags can subject equipment to stress and thermal cycling, potentially leading to premature wear and failure of components such as power supplies, motors, and electronic circuits.

Additionally, voltage sags may induce voltage spikes or transients during recovery, which can further degrade equipment reliability over time. Therefore, it's essential to implement measures such as voltage regulation, surge protection, and proper maintenance practices to minimise the risk of long-term damage caused by voltage sags.

Voltage Swells

What is a Voltage Swell?

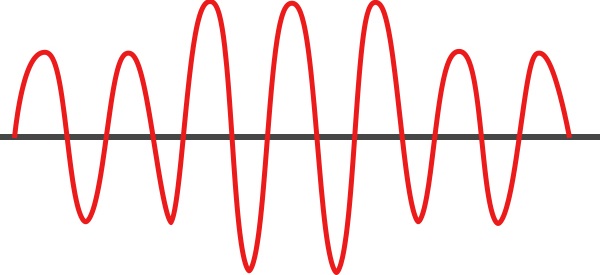

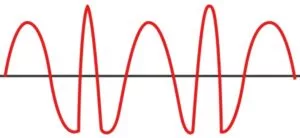

A voltage swell refers to the opposite of a voltage dip. It characterises instances where there is a sudden increase in voltage, exceeding 10% or more above the normal or recommended usage level.

Unlike voltage dips, which entail temporary reductions in voltage, voltage swells entail temporary spikes or surges in voltage levels within an electrical system.

These surges can potentially damage sensitive electronic equipment, leading to malfunctions or premature failure if not adequately addressed. Therefore, monitoring and mitigating voltage swells are essential for maintaining the reliability and longevity of electrical systems and equipment.

What is the definition of a Voltage Swell?

Voltage swell, as defined by IEEE 1159, refers to an increase in the Root Mean Square (RMS) voltage level within an electrical system. Specifically, it involves the elevation of the RMS voltage to a range between 110% and 180% of the nominal voltage, occurring at the power frequency. These increases in voltage can persist for durations ranging from half a cycle to one minute. In simpler terms, a voltage swell describes temporary spikes or surges in voltage levels, surpassing the typical operational range, which can potentially impact the performance and reliability of electrical equipment and systems.

What are the symptoms of a Voltage Swell?

Symptoms of a voltage swell can manifest in various ways, signaling potential issues with machinery and overall power quality in a plant. These symptoms may include:

Machinery Malfunctions: Voltage swells can induce stress on machinery components, leading to malfunctions, erratic behavior, or premature wear and tear. Equipment such as motors, pumps, and control systems may experience overheating, increased vibrations, or unexpected shutdowns.

Quality Issues: Voltage swells can adversely affect the quality of output in manufacturing processes. Processes reliant on precise voltage levels, such as production lines or chemical processing, may produce defective products or inconsistent results due to voltage-induced variations.

System Instability: Repeated voltage swells can undermine the stability of the overall power distribution system within a plant. This instability may lead to fluctuations in voltage levels across different areas of the plant, potentially disrupting operations and causing equipment damage.

Risk of System Failure: In severe cases, voltage swells can escalate to the point of causing system failure. Prolonged exposure to voltage surges may overstress equipment, leading to catastrophic failures and extensive downtime for repairs or replacements.

Long-Term Damage: While voltage swells may initially appear transient, they can result in long-term damage to machinery and electrical infrastructure. Over time, repeated exposure to voltage surges can degrade equipment performance, increase maintenance requirements, and ultimately reduce the lifespan of critical assets.

Recognising these symptoms is essential for plant operators and maintenance personnel to implement appropriate measures to mitigate the impact of voltage swells.

Proactive measures such as voltage regulation, surge protection, and power quality monitoring can help safeguard machinery and maintain the overall reliability of power systems within the plant.

What causes Voltage Swells?

Voltage swells are primarily caused by sudden changes in load impedance within an electrical system. These changes often occur when large loads, such as motors, furnaces, or large welders, switch off abruptly. When these heavy loads deactivate, they cause a rapid reduction in the overall load on the electrical system. As a result, the impedance of the system increases suddenly, leading to a surge in voltage levels. This phenomenon is akin to removing a constraint in a water pipe system, causing a momentary surge in water pressure. Similarly, in electrical systems, the sudden release of load leads to a temporary increase in voltage levels, resulting in a voltage swell.

How do I solve Voltage Swells?

To solve voltage swells, several popular solutions are available:

AC Voltage Stabilisers - Electro Mechanical: These devices use mechanical components to regulate voltage levels, ensuring a consistent output despite fluctuations in the input voltage. They are effective in mitigating voltage swells and maintaining stable power supply to sensitive equipment.

AC Voltage Stabilisers - Electronic (Solid State): Electronic voltage stabilisers utilise solid-state components to regulate voltage levels with precision. They offer fast response times and high accuracy in voltage regulation, making them suitable for addressing voltage swells and improving power quality.

Power Line Conditioner: Power line conditioners are comprehensive devices designed to address various power quality issues, including voltage swells. They incorporate features such as voltage regulation, surge protection, and harmonic filtering to ensure clean and stable power supply to connected equipment.

By deploying these solutions, such as AC voltage stabilisers (both electro-mechanical and electronic) or power line conditioners, businesses can effectively mitigate voltage swells and maintain a stable power supply to their critical equipment.

For tailored advice on addressing voltage swell issues specific to your requirements, you can contact our engineers at Claude Lyons for personalised assistance and solutions.

Undervoltage

What is Undervoltage?

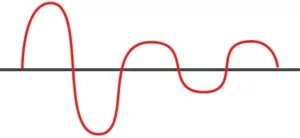

Undervoltage refers to a situation where the average voltage within a power system falls below the intended levels for a duration exceeding one minute.

In simpler terms, it occurs when the voltage supplied to electrical equipment or systems dips below the specified threshold for an extended period, potentially compromising their performance or functionality.

Undervoltage can result from various factors such as inadequate power generation, distribution system faults, or high demand exceeding supply capacity.

Identifying and addressing undervoltage issues promptly is crucial to ensure the stability and reliability of electrical systems and prevent damage to sensitive equipment.

What are the symptoms of Undervoltage?

Symptoms of undervoltage can manifest in various ways, indicating potential issues within an electrical system. Some common symptoms include:

Overheating and Premature Failure of Motors: Undervoltage can cause motors to operate at higher currents than usual, leading to increased heat generation. This elevated temperature can accelerate wear and tear on motor components, ultimately resulting in premature failure or reduced lifespan.

Dimming of Incandescent Lighting: Undervoltage can cause a decrease in the brightness of incandescent lighting fixtures. This dimming effect is a result of the reduced voltage supplied to the bulbs, impacting their luminosity and overall illumination quality.

Inadequate Battery Recharging: Undervoltage may affect the charging process of batteries, causing them to recharge improperly or incompletely. This can result in reduced battery capacity, shorter operational lifespans, or even complete battery failure over time.

Recognising these symptoms is crucial for identifying undervoltage issues and implementing appropriate corrective measures.

Addressing undervoltage promptly helps to safeguard equipment performance, maintain operational efficiency, and prevent potential safety hazards within the electrical system.

What causes Undervoltage?

Undervoltage often occurs from low grid distribution voltage because of heavily loaded circuits that result in considerable voltage drop, switching on a large load or multiple loads, or a large capacitor bank switching off.

Surges and Overvoltages

What are Surges and Overvoltages?

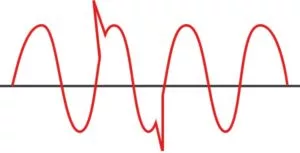

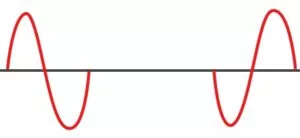

Surges, also referred to as transients, are sudden and brief spikes or disturbances in the voltage waveform of an electrical system. These overvoltage events can occur unpredictably and have the potential to cause damage, degradation, or even destruction of electrical and electronic equipment.

Surges can affect various settings, including residential homes, commercial buildings, industrial facilities, and manufacturing plants. Recognising and mitigating surges is essential to safeguarding the reliability and longevity of equipment within these environments.

How are Surges and Overvoltages defined?

A surge, or overvoltage, is defined as a sudden and significant increase in voltage that persists for a duration of three nanoseconds or longer. These voltage surges can pose risks to electrical and electronic equipment, potentially causing damage or degradation if left unaddressed.

What are the symptoms of Surges and Overvoltages?

Symptoms of surges and overvoltages may include:

Premature System Failure: Electrical and electronic systems experiencing power surges or overvoltages are prone to premature failure. The excessive voltage places additional stress on system components, accelerating their degradation and reducing their operational lifespan. This increased stress can lead to component failures, system malfunctions, or complete system breakdowns.

Component Stress: High voltages resulting from surges and overvoltages subject system components to increased stress levels. This elevated stress can manifest as overheating, increased current flow, or voltage breakdown, further exacerbating component wear and tear.

Degradation Over Time: Continuous exposure to surges and overvoltages can lead to gradual degradation of system components. Over time, this degradation may compromise the performance and reliability of the affected systems, increasing the likelihood of failures or malfunctions.

Recognising these symptoms is crucial for implementing effective mitigation measures to protect electrical and electronic systems from the detrimental effects of surges and overvoltages.

Measures such as surge protection devices, voltage regulation, and power conditioning can help mitigate the impact of surges and overvoltages, safeguarding system reliability and longevity.

What causes Surges and Overvoltages?

Surges and overvoltages are typically caused by two main factors:

Lightning Impulses: Lightning strikes, whether direct or nearby, can induce extremely high-voltage impulses into electrical systems. These impulses propagate through power lines, causing surges and overvoltages that can damage or disrupt equipment connected to the system.

Switching Impulses: Rapid switching operations within the electrical system, such as turning off a large load like motors or transformers, can generate transient voltage spikes known as switching impulses. These impulses result from the sudden interruption or change in the flow of current, leading to surges and overvoltages that can impact the stability and integrity of the electrical system.

How do I solve Surges and Over Voltages?

To solve surges and overvoltages, several popular solutions are available:

AC Voltage Stabilizers - Electro Mechanical: These devices use mechanical components to regulate voltage levels, ensuring a consistent output despite fluctuations in the input voltage. They are effective in mitigating surges and overvoltages and maintaining stable power supply to sensitive equipment.

AC Voltage Stabilizers - Electronic (Solid State): Electronic voltage stabilisers utilise solid-state components to regulate voltage levels with precision. They offer fast response times and high accuracy in voltage regulation, making them suitable for addressing surges and overvoltages and improving power quality.

UPS (Uninterruptible Power Supply): UPS systems provide backup power during surges, overvoltages, or power outages. They ensure the continuous operation of critical equipment by switching to battery power or other alternative sources when the main power supply is disrupted.

Power Line Conditioner: Power line conditioners are comprehensive devices designed to address various power quality issues, including surges and overvoltages. They incorporate features such as voltage regulation, surge protection, and harmonic filtering to ensure clean and stable power supply to connected equipment.

By deploying these solutions, such as AC voltage stabilisers (both electro-mechanical and electronic), UPS systems, or power line conditioners, businesses can effectively mitigate surges and overvoltages and maintain a stable power supply to their critical equipment.

For tailored advice on addressing surges and overvoltage issues specific to your requirements, you can contact our engineers at Claude Lyons for personalised assistance and solutions.

Brownouts

What are Brownouts?

Brownouts occur when the voltage supplied by the mains power grid drops below the typical or intended level. Similar to voltage sags, brownouts represent a temporary reduction in voltage, but they can persist for longer durations ranging from a few minutes to several hours or even days.

During a brownout, the reduced voltage level can affect the performance and reliability of electrical equipment and systems, potentially leading to disruptions in operations or damage to sensitive devices.

Recognising and addressing brownouts promptly is crucial to maintain the stability and functionality of electrical systems and prevent adverse effects on connected equipment.

What is the definition of Brownouts?

The definition of a brownout is an intentional or unintentional decrease in the electrical power supply.

During a brownout, the voltage level provided by the power grid drops below the usual or intended level. Brownouts can vary in duration, ranging from a few seconds to several hours or even days in severe cases.

These fluctuations in voltage can impact the performance of electrical equipment and systems, potentially leading to disruptions in operations or damage to sensitive devices.

What are the symptoms of a Brownout?

Symptoms of brownouts may include:

Complete Loss of Power: Brownouts can result in the complete loss of power to systems, either momentarily or for sustained periods of time. This loss of power can disrupt operations and cause inconvenience or damage, particularly in critical environments such as industrial facilities or data centers.

Equipment Restart/Reset: During short brownouts, electrical equipment may experience restarts or resets. The fluctuation in voltage levels can cause devices to momentarily lose power, leading to automatic reboots or resets. This can disrupt workflows and potentially result in data loss or system instability.

What causes Brownouts?

Brownouts can be caused by several factors, including:

Large Industrial Equipment Activation: The sudden activation of large industrial equipment, such as machinery or motors, can lead to increased demand on the electrical system. This surge in demand may exceed the capacity of the power grid, resulting in a drop in voltage levels and causing a brownout.

Mains Supply Switching: The switching of the mains power supply, either due to grid reconfigurations or maintenance activities, can cause fluctuations in voltage levels. These fluctuations may result in a temporary decrease in voltage, leading to a brownout.

Powering of Large Motors: The startup of large motors, particularly in industrial settings, can draw significant amounts of current from the electrical system. This sudden demand can cause voltage drops, especially if the system's capacity is limited, resulting in a brownout.

Incoming Source Failure: Brownouts can also occur due to failures in the incoming power sources supplying the electrical system. These failures, such as transmission line faults or transformer malfunctions, can disrupt the supply of electricity and lead to voltage reductions.

Intentional Brownout for Load Reduction: In certain cases, utility providers may intentionally implement brownouts as a means of load reduction during emergencies or periods of high demand. By reducing the voltage supplied to customers, utilities can alleviate strain on the power grid and prevent widespread blackouts.

How do I solve Brownouts?

To solve voltage brownouts, several popular solutions are available:

AC Voltage Stabilisers - Electro Mechanical: These devices utilise mechanical components to regulate voltage levels, ensuring a consistent output despite fluctuations in the input voltage. They are effective in mitigating voltage brownouts and maintaining stable power supply to sensitive equipment.

AC Voltage Stabilisers - Electronic (Solid State): Electronic voltage stabilisers employ solid-state components to regulate voltage levels with precision. They offer fast response times and high accuracy in voltage regulation, making them suitable for addressing voltage brownouts and improving power quality.

UPS (Uninterruptible Power Supply): UPS systems provide backup power during brownouts, ensuring continuous operation of critical equipment. They switch to battery power or other alternative sources when the mains power supply is insufficient, protecting equipment from damage and downtime.

Power Line Conditioner: Power line conditioners are comprehensive devices designed to address various power quality issues, including voltage brownouts. They incorporate features such as voltage regulation, surge protection, and harmonic filtering to ensure clean and stable power supply to connected equipment.

By deploying these solutions, such as AC voltage stabilizers (both electro-mechanical and electronic), UPS systems, or power line conditioners, businesses can effectively mitigate voltage brownouts and maintain a stable power supply to their critical equipment.

For tailored advice on addressing voltage brownout issues specific to your requirements, you can contact our engineers at Claude Lyons for personalised assistance and solutions.

High Voltage Spikes

What are High Voltage Spikes?

High voltage spikes, in electrical engineering, refer to rapid and brief electrical transients characterised by a sudden increase in voltage within an electrical circuit. These spikes manifest as rapid fluctuations in voltage levels, often occurring within microseconds or milliseconds. High voltage spikes can result from various sources such as lightning strikes, switching operations, or electromagnetic interference.

They pose risks to electrical equipment and systems, potentially causing damage or malfunction if not adequately managed. Therefore, understanding and mitigating high voltage spikes are essential for maintaining the reliability and integrity of electrical infrastructure.

What is the definition of a High Voltage Spike?

The definition of a high voltage spike refers to a sudden increase in voltage lasting for less than three nanoseconds. It's distinguished from a voltage surge, which is a sudden voltage increase lasting for three nanoseconds or more. These spikes are rapid and transient electrical events, posing potential risks to electrical equipment and systems if not properly managed. Understanding the distinction between spikes and surges is essential for implementing appropriate protection measures in electrical engineering applications.

What are the symptoms of High Voltage Spikes?

Symptoms of high voltage spikes within an electrical circuit may include:

Equipment Locking: High voltage spikes can cause electronic equipment to become unresponsive or "lock up," preventing normal operation.

Crashing: Electronic devices may experience sudden crashes or shutdowns when exposed to high voltage spikes, leading to data loss or system instability.

Damage: The sudden surge in voltage during spikes can cause damage to sensitive components within electronic equipment, such as integrated circuits or microprocessors.

Complete System Failure: In severe cases, high voltage spikes can lead to complete system failure, rendering the affected equipment inoperable.

Recognising these symptoms is crucial for implementing protective measures, such as surge protection devices, to safeguard electronic equipment from the adverse effects of high voltage spikes.

What causes High Voltage Spikes?

High voltage spikes are frequently caused by various factors, including:

Switching on Equipment: The switching on or off of equipment, particularly heavy inductive loads such as motors or transformers, can induce sudden voltage spikes due to the abrupt change in current flow.

Magnetic Fields: Magnetic fields generated by nearby equipment or external sources can induce voltage spikes in neighbouring circuits, especially if they intersect with conductive paths.

Electrical Disturbances: Events such as lightning strikes or electromagnetic interference can introduce rapid and significant fluctuations in voltage levels, resulting in high voltage spikes in electrical systems.

Understanding the potential sources of high voltage spikes is essential for implementing preventive measures, such as surge protection devices, to mitigate their impact and protect sensitive equipment from damage or malfunction.

How do I solve High Voltage Spikes?

To address high voltage spikes, several popular solutions are available:

AC Voltage Stabilisers - Electro Mechanical: These devices use mechanical components to regulate voltage levels, ensuring a consistent output despite fluctuations in input voltage. They are effective in mitigating high voltage spikes and maintaining stable power supply to sensitive equipment.

AC Voltage Stabilisers - Electronic (Solid State): Electronic voltage stabilisers utilise solid-state components to regulate voltage levels with precision. They offer fast response times and high accuracy in voltage regulation, making them suitable for addressing high voltage spikes and improving power quality.

UPS (Uninterruptible Power Supply): UPS systems provide backup power during high voltage spikes or power outages. They ensure continuous operation of critical equipment by switching to battery power or other alternative sources when the main power supply is disrupted.

Isolation Transformer: Isolation transformers provide electrical isolation between the input and output circuits, effectively blocking high voltage spikes from passing through to connected equipment. They offer an additional layer of protection against voltage transients.

Power Line Conditioner: Power line conditioners are comprehensive devices designed to address various power quality issues, including high voltage spikes. They incorporate features such as voltage regulation, surge protection, and harmonic filtering to ensure clean and stable power supply to connected equipment.

Contacting our engineers at Claude Lyons can provide personalised assistance and solutions tailored to your specific needs and challenges related to high voltage spikes. We can help evaluate your requirements and recommend the most suitable solution to mitigate the impact of high voltage spikes on your electrical systems and equipment.

Electrical Noise

What is Electrical Noise?

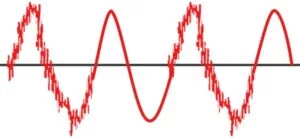

Electrical noise refers to the unwanted disturbance in an electrical signal, which is caused by the coupling of random electrical signals into circuits. This interference can be generated by various effects within electrical systems.

What is the definition of Electrical Noise?

In electrical systems, noise is an unwanted disturbance in an electrical signal. It is generated by several different effects and can vary greatly in its characteristics.

What are the symptoms of Electrical Noise?

Symptoms of electrical noise include system lock-ups, system resets, damaged PCBs, and disruption to visual or audio equipment. These symptoms can manifest in various forms depending on the type and severity of the noise.

What causes Electrical Noise?

Electrical noise can originate from both internal and external sources. Internal noise may result from faults in switchgear or the electrical design itself, while external noise can be caused by lightning, electrical storms, electromagnetic interference from currents in cables, and frequency interference from equipment such as RF transmitters or microwave radiation.

How do I solve Electrical Noise?

Popular solutions to electrical noise include deploying UPS (Uninterruptible Power Supply), isolation transformers, and power line conditioners.

These solutions help mitigate the impact of electrical noise on sensitive equipment. For personalised assistance and solutions tailored to your specific electrical noise issues, contact our engineers at Claude Lyons.

Electrical Blackouts

What is the definition of an Electrical Blackout?

An electrical blackout is a significant disruption in the electricity supply characterised by a complete failure, resulting in the cessation of power distribution. These events, varying in duration from mere seconds to prolonged periods spanning hours or even days, entail the loss of electrical power to affected regions, infrastructure, or facilities.

What are Voltage Blackouts?

Voltage blackouts denote instances of total electrical supply failure within electrical systems, synonymous with mains failure. This cessation of voltage transmission can lead to the abrupt halt of operations and functions dependent on electricity, affecting a broad spectrum of equipment and systems.

What are the symptoms of Blackouts?

Symptoms of blackouts encompass the comprehensive loss or interruption of operational functionality across various systems. Despite potentially fleeting durations, these disruptions suffice to prompt equipment resets or crashes, impacting operational continuity and potentially causing data loss or system instability.

What causes Blackouts?

Blackouts can arise from diverse sources, including faults at power stations, damage to electric transmission lines, substations, or equipment failure such as fuses or circuit breakers. These events, whether due to natural disasters, infrastructure failures, or equipment malfunctions, precipitate the sudden and widespread loss of electrical power.

How do I solve Blackouts?

Addressing blackouts necessitates robust solutions to ensure uninterrupted power supply. Popular strategies include deploying UPS (Uninterruptible Power Supply) systems, which provide backup power during outages, renewable energy systems integrated with battery storage for continuous power generation, and generators for emergency power generation. Each solution offers varying degrees of resilience and reliability in mitigating the impact of blackouts on critical operations. For tailored recommendations and implementation strategies, consulting our engineers at Claude Lyons can provide expert insights and solutions tailored to your specific blackout mitigation needs.

Contact Us

Have another question? Need more info? Contact us below!

ABOUT US

Claude Lyons, a UK brand established in 1918, has been a pioneer in voltage and power control, making significant advancements in energy saving and harmonic mitigation, and is globally recognised for its voltage stabilisers, power conditioning and uninterruptible power supplies (UPS). In 2016, Allendale Group Ltd acquired Claude Lyons’ trademarks, product designs, and intellectual property, continuing the legacy of innovation and commitment to high-quality products.

Claude Lyons

Pindar Road

Hoddesdon

Hertfordshire

En11 0BZ

United Kingdom

Tel: +44 (0)1992 455 930

Email: sales@claudelyons.com

Claude Lyons Ltd is a subsidiary company of Allendale Group Ltd.