APPLICATIONS

Resources

Frequently Asked Questions

Elevate Your Broadcast Infrastructure: Voltage Management Solutions

General Questions

Voltage Optimisation (PowerSave) Questions

Frequency Converter Questions

Regavolt Autotransformer Questions

Installation and Servicing Questions

Contact Us

Have a question regarding an application? Need more info? Contact us below!

ABOUT US

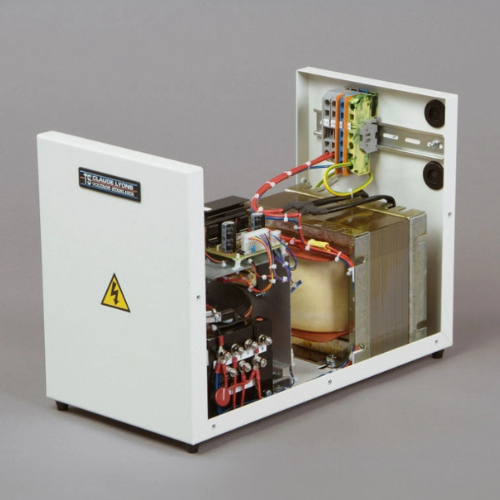

Claude Lyons, a UK brand established in 1918, has been a pioneer in voltage and power control, making significant advancements in energy saving and harmonic mitigation, and is globally recognised for its voltage stabilisers, power conditioning and uninterruptible power supplies (UPS). In 2016, Allendale Group Ltd acquired Claude Lyons’ trademarks, product designs, and intellectual property, continuing the legacy of innovation and commitment to high-quality products.

Allendale Group Ltd

Pindar Road

Hoddesdon

Hertfordshire

EN11 0BZ

United Kingdom

Tel: +44 (0)1992 455 930

Email: sales@claudelyons.com

Claude Lyons Ltd is a subsidiary company of Allendale Group Ltd.