A Timeline of the Variable Transformer

Claude Lyons has a rich history in developing variable transformers, dating back to 1933. Our timeline details the evolution of these essential components, showcasing significant milestones and innovations over the decades. Additionally, we provide a handy table of old part numbers, making it easier for you to reference and understand the legacy products. Explore the journey of Claude Lyons and discover how our commitment to quality and innovation has shaped the industry.

Origins: Introducing the Variac

Originally introduced commercially as the “Variac”™ in 1933 by the former General Radio Company of Cambridge, Massachusetts, the patent covered the design of the carbon brush gear essential to smoothly vary the voltage. The earliest Variacs™ employed a toroidal core comprising a stack of ring laminations, with a single-layer winding of insulated copper wire, bared to form what is essentially a commutator, across which a carbon contact is moved to select the output voltage.

Evolution: Advancements and Challenges

The main developments in subsequent years included the replacement of the stacked core by a spiral strip wound core in the 1950s, permitting operation at higher flux density and providing higher output capability with lower no-load losses. Additionally, the introduction of a hard precious-metal coating to the contact surface improved performance under surge conditions and extended product lifetime, designated as the V series. The V series was later succeeded by the Regulac R series in the late 1960s.

Technological Innovations: Enhancing Performance

The first models were rated at some 500 VA (200 series), followed by larger units rated at about 2 kVA (100 series) and subsequently 5 kVA (50 series). Initially imported from the USA, Variacs™ faced challenges with 50Hz supplies, leading to manufacturing in England from 1936 onwards. This transition facilitated full operation on 50Hz supply and with overvoltage capabilities.

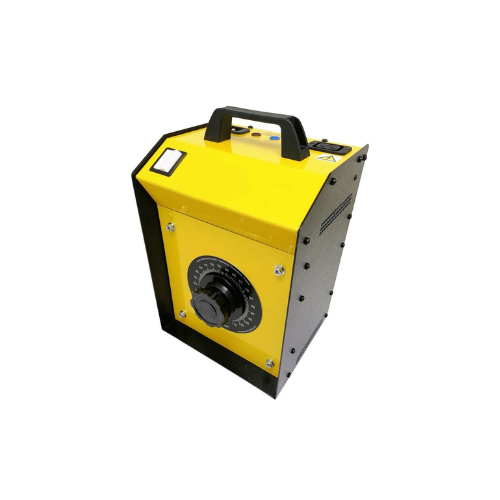

Expansion and Consolidation: Regavolt and Varatran

With the acquisition of the product ranges of Berco Controls Limited and The Zenith Electric Company Limited, the range was rationalised under the UK Registered Trademarks Regavolt® and Varatran®, encompassing epoxy-encapsulated variable transformers.

Durability and Support: Ensuring Longevity

Many variable transformers supplied by the company have remained in service for over 50 or 60 years, a testament to their durability. With proper care and maintenance, these units can enjoy an almost indefinite lifespan. Refurbishment of old units is often possible, but replacements are available for those damaged due to misuse or overload. The company remains committed to offering suitable replacements for its models and those of other manufacturers, ensuring continued customer satisfaction.

Product Overview: Historical Models and Variants

The table below showcases basic historic 115-120V, 230-240V, and 440V 50/60 Hz models, serving as a guide to the various series and their current production equivalents. Variants include ganged models for higher power and/or three-phase operation, high-frequency units, and units for lower and higher supply voltage.

| Operating Voltage | Approximate trademark date and model number | ||||

| 1930s - 1940s "Variac"™ | 1940s - 1960s "Variac"™ | 1940s - 1970s Regavolt®(Berco) | 1960s - 1970s Regulac® | 1970s - Present Regavolt® | |

| 230-240V 115-120V |

200B |

X1,X2 |

31A,31B,31C |

RX1,RX1L |

301 301L |

| 230-240V 115-120V 440V |

200-CUH, CMH |

V3H - V6H (M) V3 - V6(M) |

41 - 45A, C 41B, 42B |  RB1 - 4 (M) RB1L - 3L (M) RB1 - 4 (M) RB1L - 3L (M)RB2H - 4H (M) |  401 - 404 (M) 402L, 403L (M) 402H, 404H (M) 401 - 404 (M) 402L, 403L (M) 402H, 404H (M) |

| 230-240V 115-120V 440V |  100-R, 100-L* 100-R, 100-L*100-Q, 100-K* | 100-R, 100-L* Continued production |  71,72A, C,71B 71,72A, C,71B71Z, 72Z |  RK6 - 13 (M),RK6L, RK6L-M RK6 - 13 (M),RK6L, RK6L-MRK6H - 13H (M) |  706 - 715 (M), 706L, 706L-M 706 - 715 (M), 706L, 706L-M706H - 715H (M) |

| 230-240V |

| No direct replacement - use 715 or 1225 use 715 or 1225 | |||

| 230-240V 115-120V 440V |  50B, 50B-M 50B, 50B-M50A, 50A-M | 50B, 50B-M Continued production |  121A, C 121A, C |  RQ25, RQ25-M RQ25, RQ25-MRQ25L, RQ25L-M RQ25H, RQ25H-M |  1225(M) 1225(M)1225L (M) 1225H (M) |

View Our Product Solutions

View our Regavolt and Portavolt Transformers by clicking the button below

ABOUT US

Claude Lyons, a UK brand established in 1918, has been a pioneer in voltage and power control, making significant advancements in energy saving and harmonic mitigation, and is globally recognised for its voltage stabilisers, power conditioning and uninterruptible power supplies (UPS). In 2016, Allendale Group Ltd acquired Claude Lyons’ trademarks, product designs, and intellectual property, continuing the legacy of innovation and commitment to high-quality products.

Claude Lyons

Pindar Road

Hoddesdon

Hertfordshire

En11 0BZ

United Kingdom

Tel: +44 (0)1992 455 930

Email: sales@claudelyons.com

Claude Lyons Ltd is a subsidiary company of Allendale Group Ltd.

V30H, V30H-M

V30H, V30H-M